Autodesk recently announced that it’s teaming up with

bioprinting company Organovo to develop software that can design human

tissue to be printed out on 3-D printers. In the near future, the

printed organs are expected to be used in research. But down the line,

they could end up inside real, live humans—an alternative to today’s

inefficient organ donation process.

Organovo is known for creating the first commercial 3-D bioprinters

back in 2010; as of September 2012, the company had produced 10

bioprinters, each of which reportedly costs hundreds of thousands of

dollars. Created with technology from biophysicist Gabor Forgacs (he’s

also the co-founder of test tube meat and leather startup Modern

Meadow—and the father of the other cofounder, Andras Forgacs),

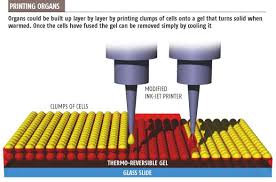

Organovo’s NovoGen MMX Bioprinter shapes cells—often stem cells from a

donor—into 3-D tissue that’s theoretically as good as anything created

by the human body. Clinical testing is still years away.

The partnership with Autodesk isn’t completely unexpected. Autodesk’s

Bio/Nano Programmable Matter research group collaborates with outside

researchers on design software’s role in biotechnology.

Hod Lipson, head of Cornell’s Creative Machines Lab, explained the

need for design software in organ printing in a Wall Street

Journalarticle: “We have machines that can make almost anything, but we

don’t have the design tools,” he said. “In bioprinting, there is no

computer-aided design software for body parts.”

As surgeon Anthony Atala demonstrated on the TED stage in 2011,

printable organs really aren’t that far from becoming reality (as long

as the FDA doesn’t get in the way). Body part design software only

speeds up the process.